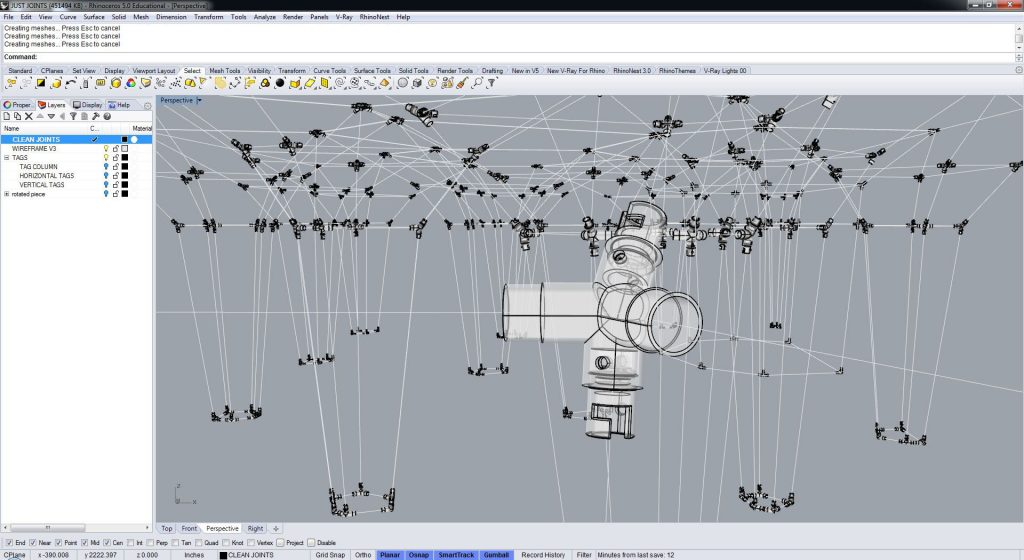

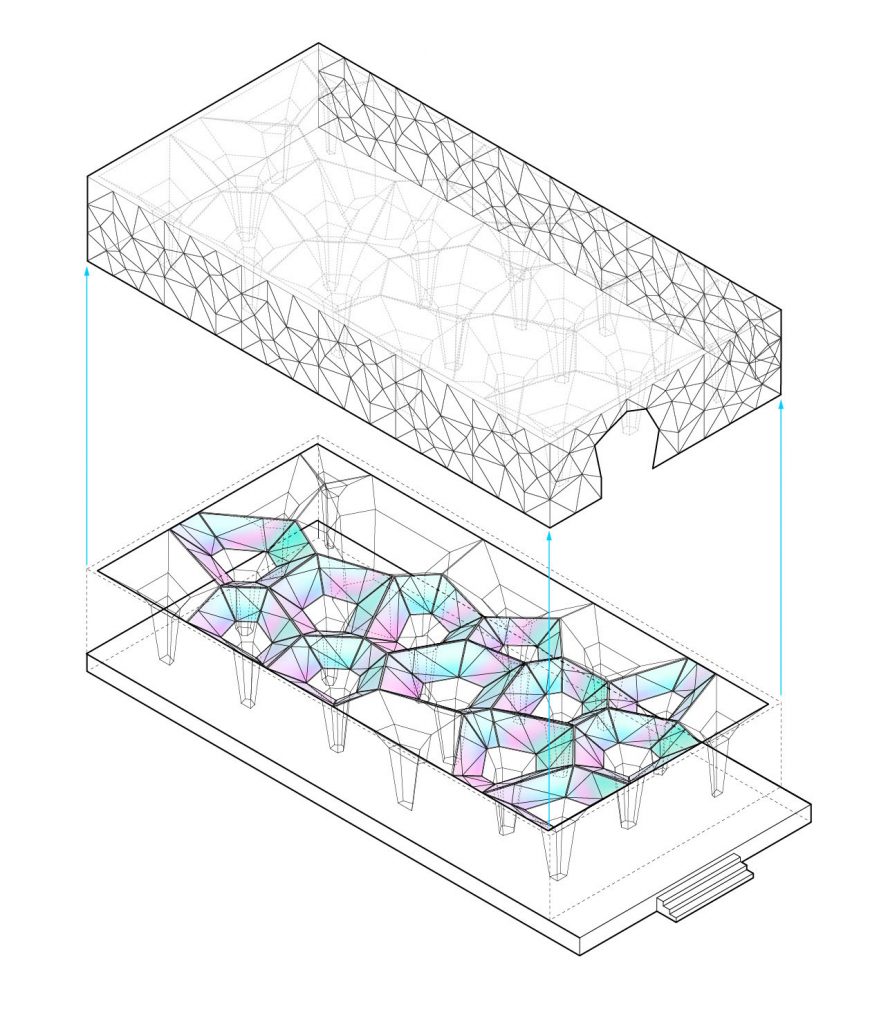

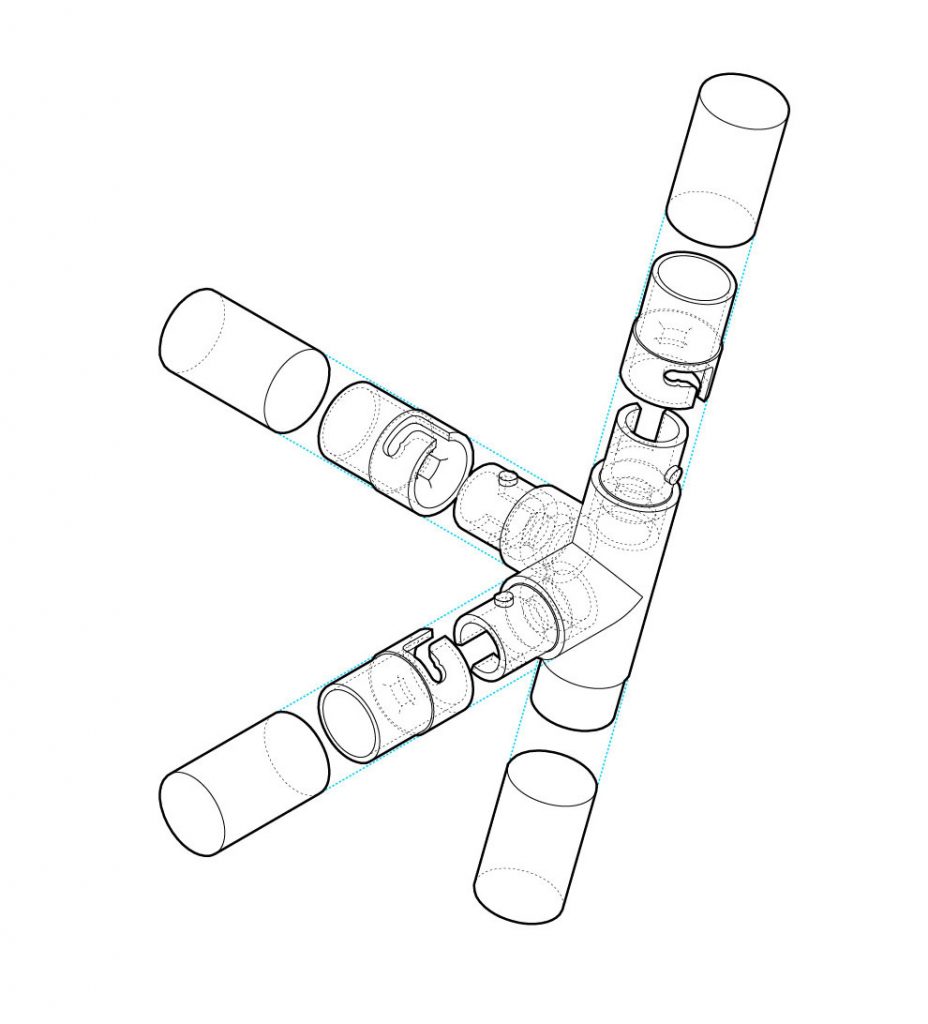

We worked with 3M on a temporary environment at SXSW in Austin. The space was meant to showcase the large spectrum of industries their products serve. As a showcase of there products we also chose to construct the space out of 3M materials as well. We came up with a cellular structure that would cast colored light into the space using 3M’s dichroic. Each one of these cells came down into a podium that showcase a product. The columns and interior surfaces were all laminated with 3M’s Di-noc eraser board laminate that would receive the filtered light in a vibrant way. The cellular was made of 100s of unique lengths of aluminum tube. The space had an install window of a couple of days so we designed a custom snap to twist and snap joint for the ends of each tube that could be 3D printed and go together quickly.

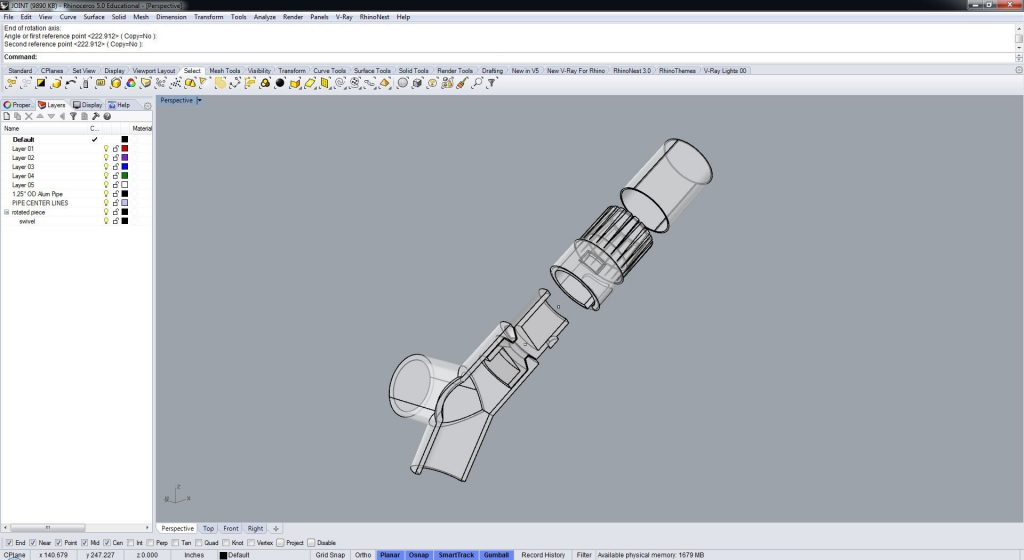

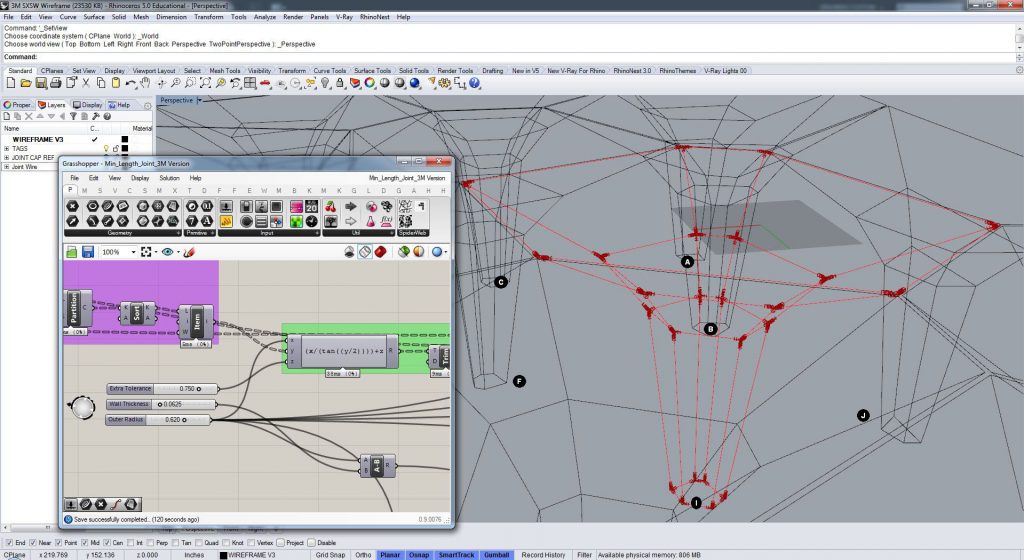

The joints were all printed out of one piece using SLS technology which allows for internal moving parts. This allowed the ends to swivel so each joint could lock into place. Each of the 2400 3D printed parts were unique so we developed all of the geometry for printing in Grasshopper and sent them directly to be printed. The foundation of the grasshopper definition can be found here.