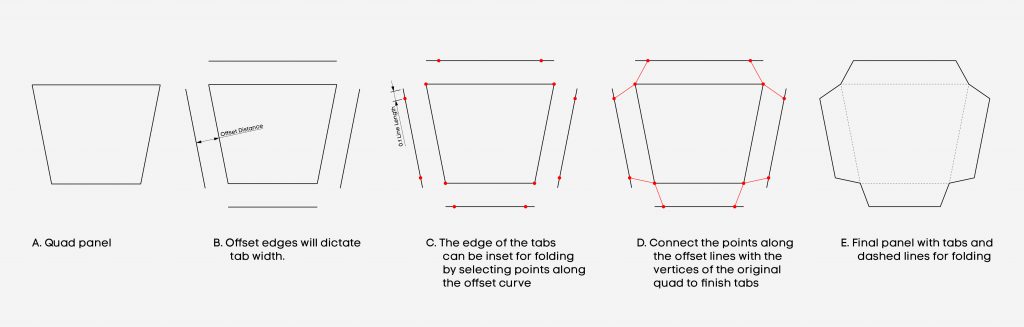

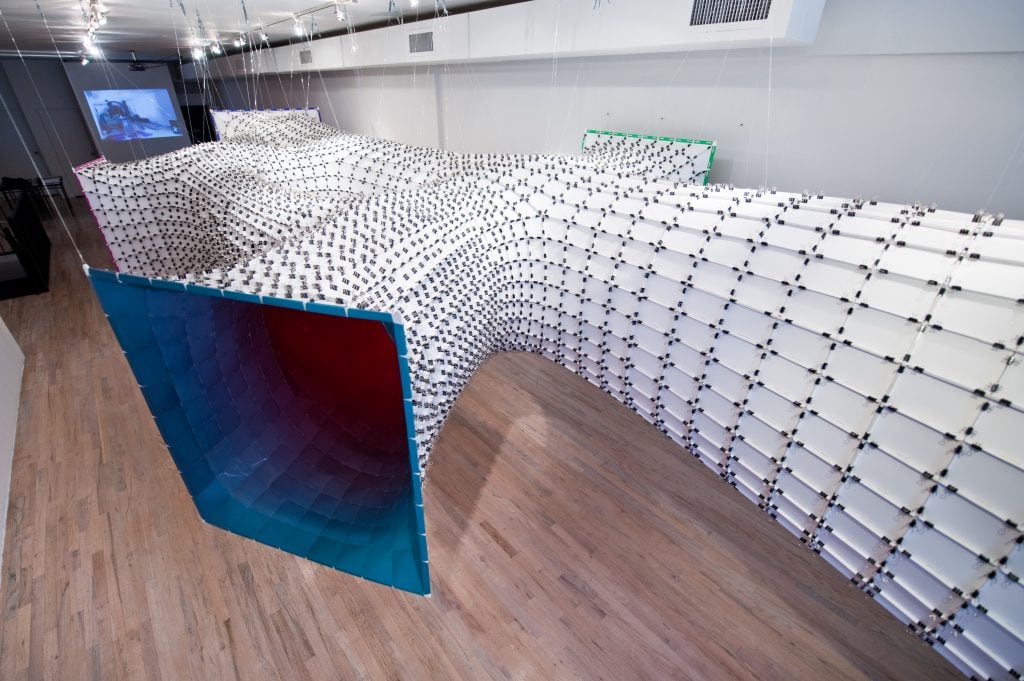

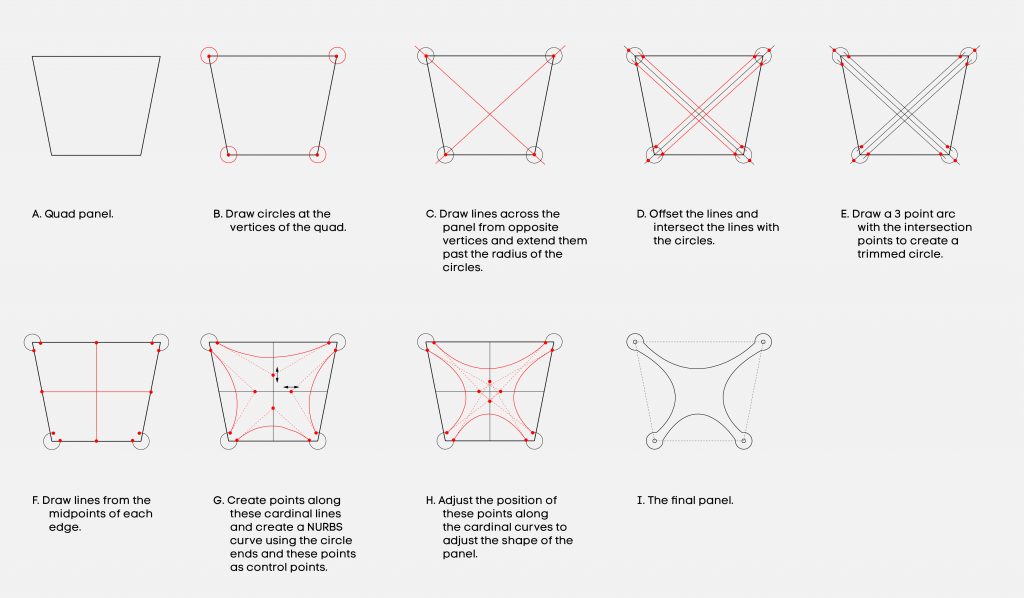

A lot of the work we do with thin form-found surfaces starts with simply flattening a model, after that a lot of work goes into creating prototypes and the necessary details to assemble the piece and potentially give it various material textures or additional assemblies. Automating these details with grasshopper is a lot like producing a drawing with construction lines. The final cut files are created with the original four-sized panel shape as the base. Below are two examples of how we have approached these assembly details.

The above example shows the general logic behind a four-sided panel with tabs that results in a continuous surface much like a shall. Here is the panel with tabs grasshopper definition: panel_tabs.zip

This example shows how the surface is rationalized into Xs where each vertex becomes an attachment point between panels. This produces more of a net. Various details can be added to receive cladding materials. Here is the X panel grasshopper definition: x_panel.zip